Tienen

We use the Google Maps map service. For a map to be shown, you first have to give your consent. If you consent, data will be transferred to Google, cookies will be used, and the Google DoubleClick advertising network will be contacted. This may trigger further data processing operations. It cannot be ruled out that data will also be transferred to countries outside the European Economic Area.

You can revoke your consent with immediate and future effect at any time by reloading the website.

1. Introduction

Tienen – More than fifty years after production began in 1974, Robert Bosch Produktie N.V. in Tienen has grown into a major player for innovation and sustainable production within Bosch. As a global development center for wiper blades and wiper rubber, Tienen plays a leading role in Bosch's international network. Worldwide, approximately 20 percent of Bosch wiper blades and 70 percent of the wiper rubber are produced in Tienen.

Bosch in Tienen is unique because the research and development, as well as the entire production process – from rubber to the packaged final product – are all housed in a single location. In fact, many wiper innovations originate in Tienen. The production in Tienen focuses on wiper blades for the replacement market (aftermarket), and on wiper rubbers. Even in times of electricfication and automated driving, the wiper blade remains a crucial safety component; besides a clear view for the driver many sensors behind the windshield need a proper cleaning to work efficiently.

50 years of Bosch in Tienen

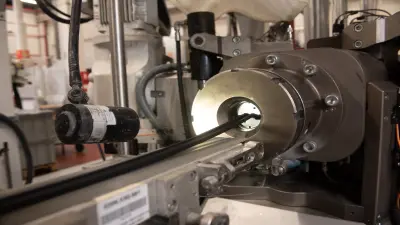

In 2024, 11 million euros was invested in an additional, state-of-the-art rubber extrusion line to meet the increasing demand for wiper rubber, and in two plastic extrusion lines for the in-house production of wiper blade spoilers. In 2025, a brand-new packaging line will also be put into operation.

"With our advanced technologies and extensive know-how, we are ideally positioned to provide our customers worldwide with high-quality solutions," says Werner Richter, plant manager of Robert Bosch Produktie N.V. "Together with all our employees, we are shaping the future in R&D and production. Sustainability and responding to new trends such as autonomous and electric driving and digitization are central to this."

Timeline of important innovations from Bosch in Tienen

2. Future-proof, high-quality wiper blade production

Bosch in Tienen produces Aerotwin wiper blades. The factory utilizes advanced, automated production lines with low cycle times and high efficiency. Modern techniques (for example: ultrasonic welding), strict quality standards, and built-in controls ensure that every wiper blade meets the highest requirements. The experienced team continuously develops and implements new production and measurement processes, not only for its own production but also for sister companies worldwide.

The Aerotwin wiper blade, the flagship of Robert Bosch Produktie N.V., is known for its unique dual spring strip, which perfectly adapts to the curvature of the windshield. Thanks to the aerodynamic profile, the wiper is not lifted at higher speeds, ensuring optimal sealing, wipe quality and noise performance.

The Power Protection Plus rubber, featuring a patented coating, is formulated according to a unique, high-quality recipe. The rubber profile consists of a flexible hinge and a wear-resistant edge with a low friction powder coating on top. This technology ensures streak-free wiping in all weather conditions.

Loading the video requires your consent. If you agree by clicking on the Play icon, the video will load and data will be transmitted to Google as well as information will be accessed and stored by Google on your device. Google may be able to link these data or information with existing data.